Inventory Planning & Optimization

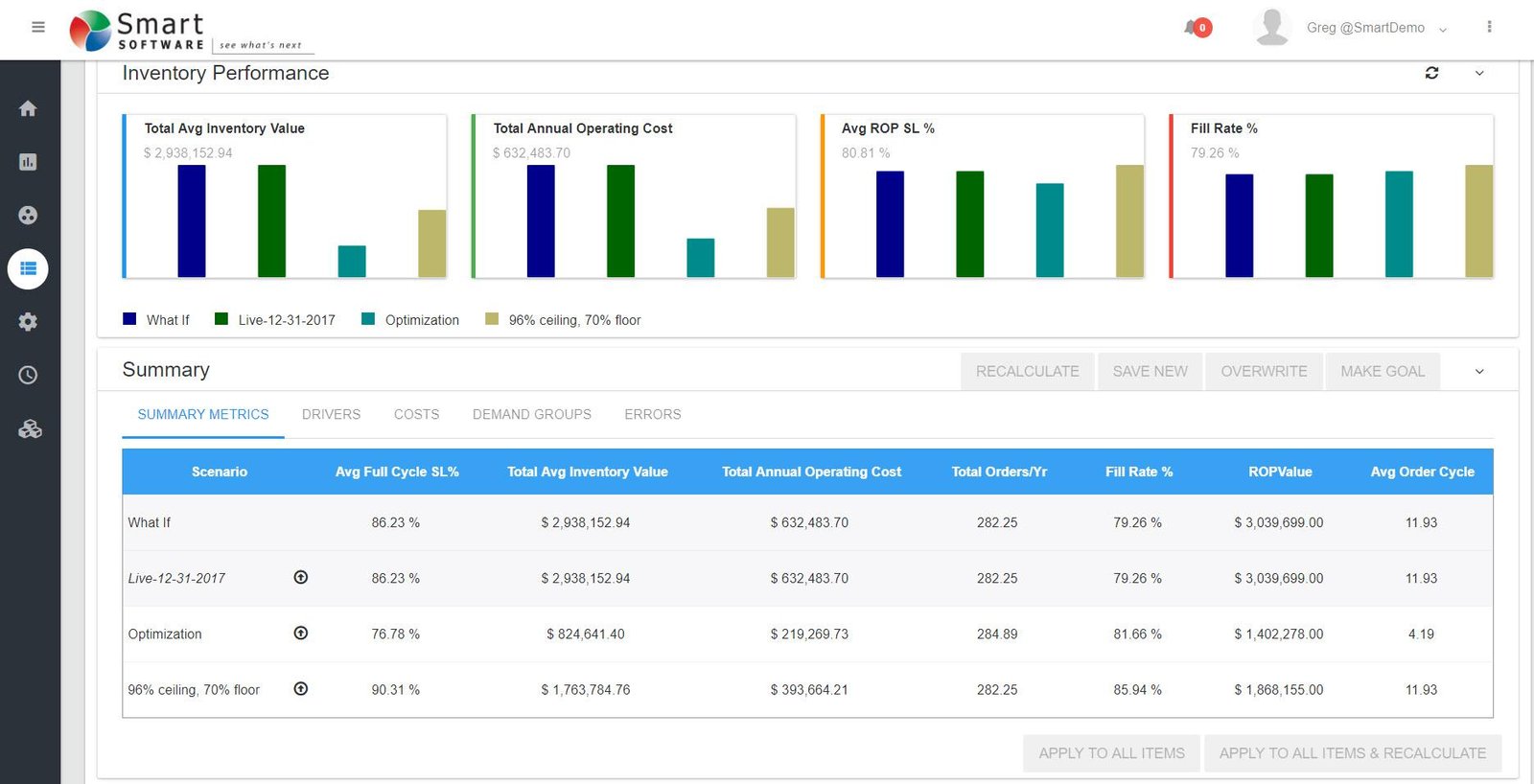

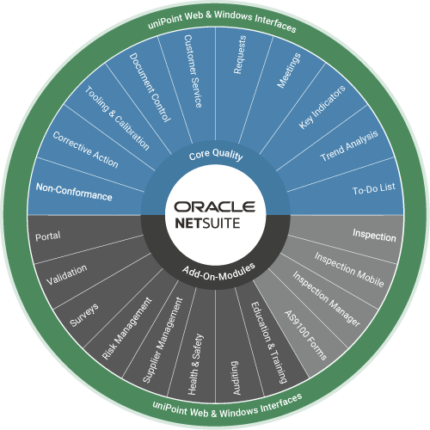

Smart Inventory Optimization (SIO) delivers inventory policy decision support and the means to share and collaborate and track the impact of your inventory planning policy. You can forecast projected metrics such as service level, fill rate, holding costs, ordering costs, stock out costs. Users can identify overstocks, under stocks, re forecast optimal stocking policies and share proposed policies with other stakeholders, collect feedback and establish a consensus inventory plan. And unlike traditional inventory planning systems that rely on rule of thumb approaches or require the user to arbitrarily set sub optimal service level targets. Smart Inventory Optimization prescribes the optimal service levels for you. Users can optionally assign service level constraints to ensure the optimization engine respects business rules. SIO provides the required inventory planning parameters for a variety of NetSuite replenishment policies such as Reorder Point/Order Quantity and Min/Max and Safety Stock Planning and Demand Management and more

Key Benefits

With Smart Inventory Optimization you will be able to reduce inventory levels and increase service levels and improve planner productivity. The easy to use interface will enable you to:

- Identify where you are overstocked and understocked.

- Modify planning parameters based on your business rules and service targets, and inventory budget

- Leverage optimization logic in SIO to prescribe planning parameters and service levels for you.

- Compare proposed policies to the benchmark

- Collaborate and develop a consensus inventory plan

- Automatically generate revised planning parameters as demand and other inputs change

True Web Platform

- 100% web app

- Thin Client

- Multi Tenant