Lot Based Manufacturing

- Manufacturing Industry, especially fabless Semiconductor companies, has unique system requirements to run their subcontracted manufacturing operations.

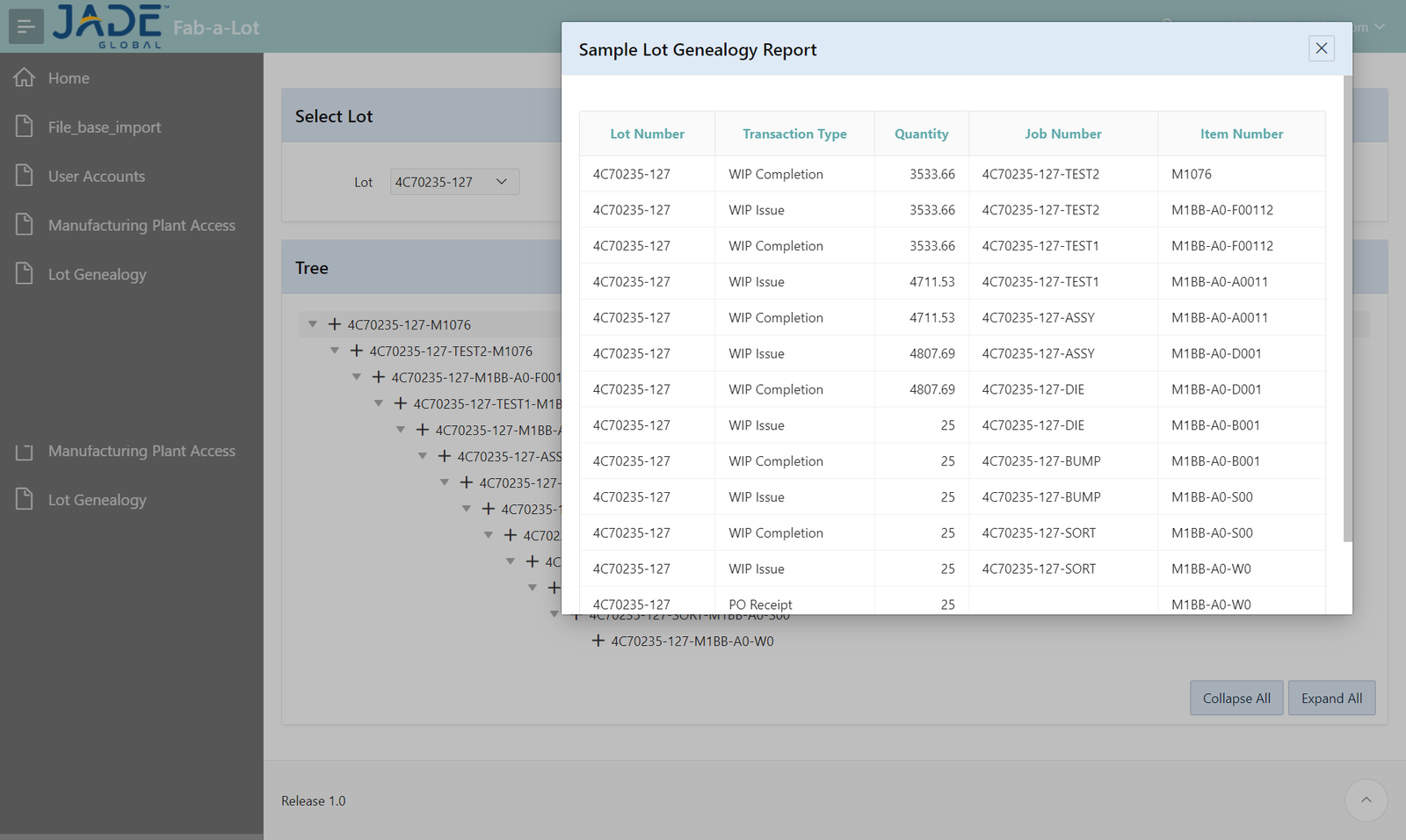

- These companies need their manufacturing applications to be tightly lot controlled, with the ability to view complete lot genealogy through their extended supply chain.

- Most semiconductor manufacturing solutions do not have features that lot-based manufacturing industries can easily use.

- However, businesses are facing challenges due to lack of solution for the Semiconductor Industry Including:

- Lack of an integrated, efficient, and digital lot-based manufacturing solution in Oracle Cloud SaaS and other ERP applications.

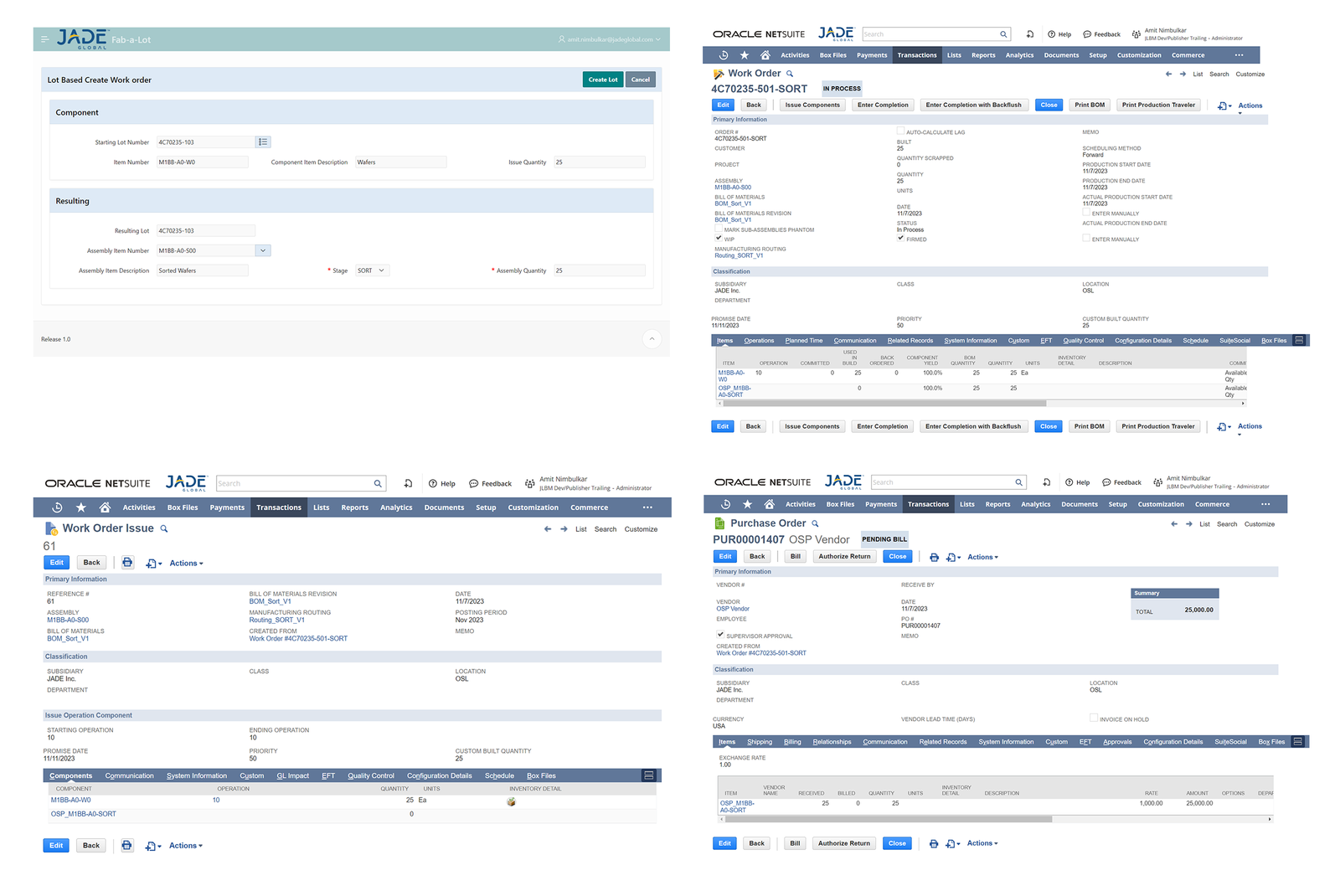

- Need for an automated and simplified lot transaction process for Oracle Industrial Manufacturing

- Need for integrations with core ERP processes such as Work in Process, Cost Accounting, Product Lifecycle Management, and Planning.

- Need for Full Lot Genealogy and Traceability to quickly trace any issues with the product.

- Ability to create a tight relationship between WIP jobs and lot numbers.

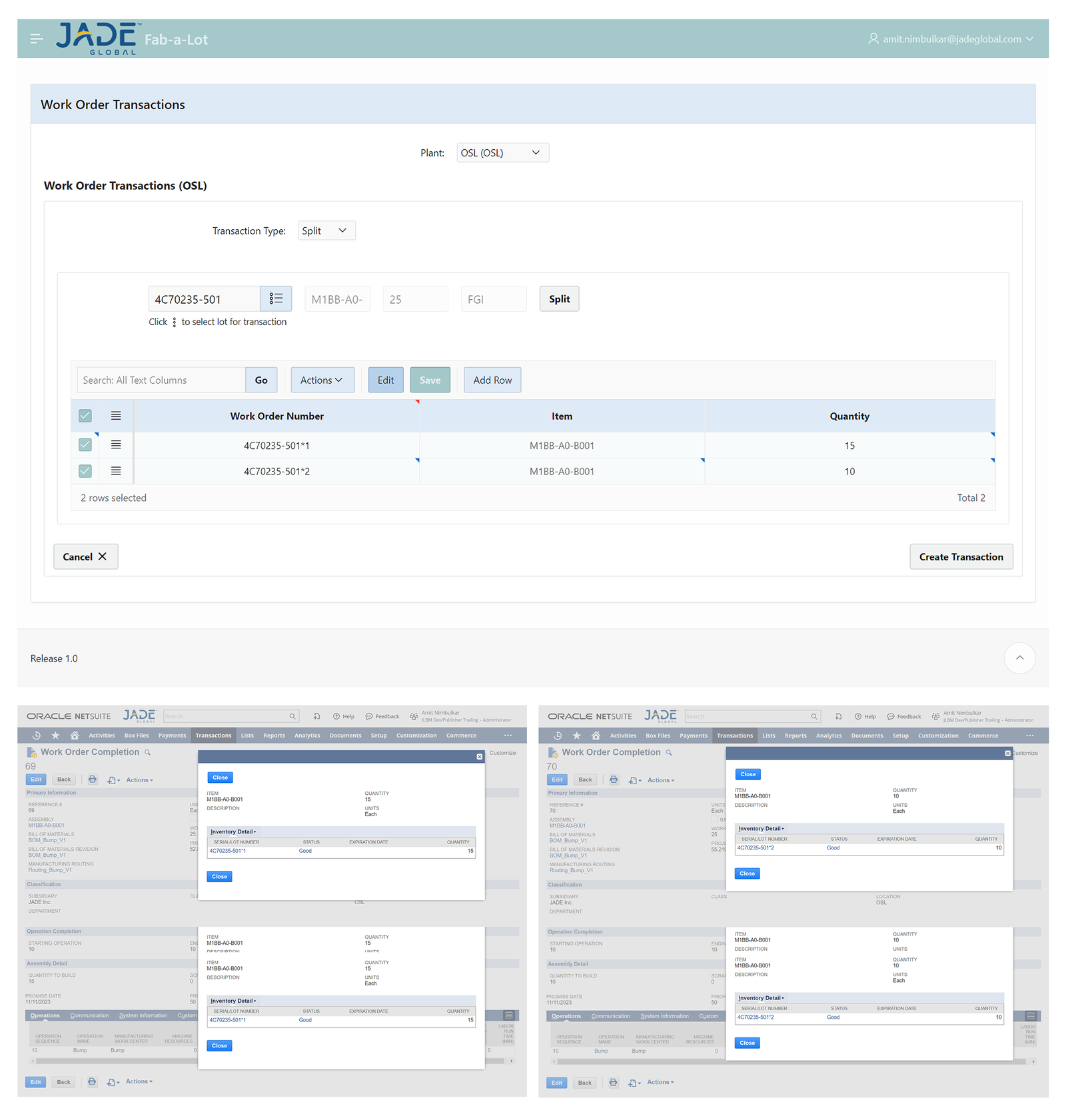

- Allow mid-process operations for WIP lots such as split, merge, and part number change.

- Ability to extend the solution for B2B integrations with Subcons for lot transaction reporting and automated processing in the system, using Industry-standard RosettaNet Platform.

- Ability to have tight integrations with Subcon outside processing purchase orders.

- Lack of out of box reporting solution for lot-based manufacturing

Key Benefits

- Get full granular visibility of your lots in WIP and in Inventory.

- Real time automated lot transaction processing eliminating costly supply chain delays that can run in days.

- Exceptions and errors are immediately visible and corrected in time with the centralized exception management process.

- The full audit trail helps our customer quickly take corrective and preventive actions to avoid costly field failures or reworks.

- Inventory levels can be better planned with dynamic real time responses due to improved visibility, potentially reducing cost of inventory by 10% and cost of lost revenue by another 10%.

- Leverage the standard functionality of Oracle Cloud SaaS/ERP COTS applications, lowering your TCO for the applications, lower upgrade costs and improve system agility.

Service Offering

- Implement Fab-a-Lot solution with NetSuite.

- Integrate with Subcon B2B Reporting Solution for automated real-time transaction processing.