Advanced Planning and scheduling (APS)

FEATURES

>Comprehensive finite capacity planning

>What-if scenario analysis

>Live schedule adherence Gantt chart

>Real-time progress feedback from the factory floor

BENEFITS

>Comprehensive finite capacity planning to model all the constraints of your supply chain and manufacturing operations

>Plans based on the real-time performance of the factory

>Provide a single source of truth for planning priorities so everyone is pulling in the same direction

>Live visibility of schedule adherence – early warnings of issues prevent the need to fire-fight

>Scenario planning and what-if analysis to understand the impact on your business of any changes to demand, production, deliveries, shift patterns etc.

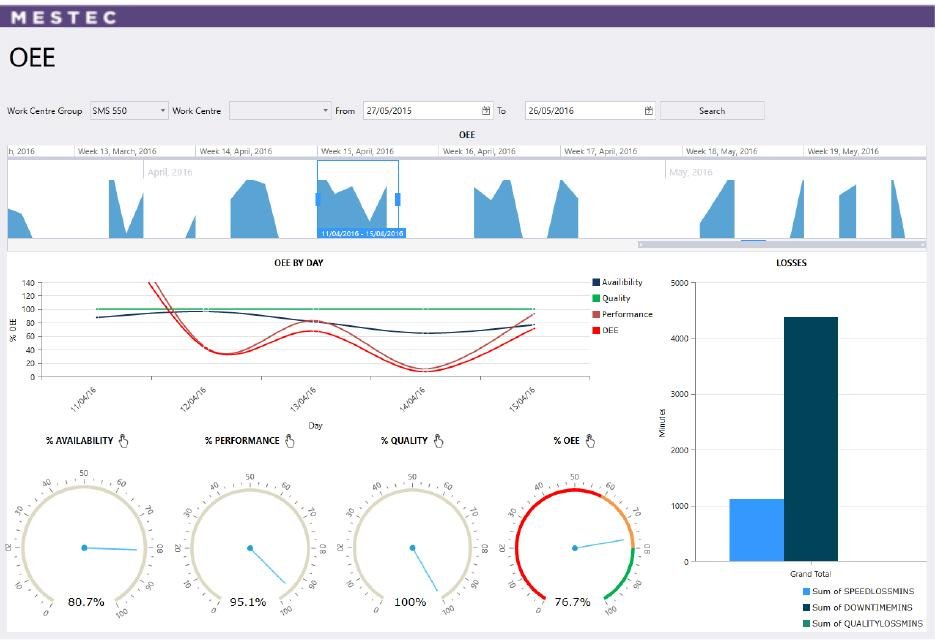

Asset Performance Management

>Down time recording

>Automatic data-acquisition

>Tool tracking & management

>Realtime OEE monitoring

Paperless Factory

FEATURES

>Electronic work-to lists

>Electronic work instructions and drawings

>Bar code scanning

>Touchscreen-based SFDC

BENEFITS

>Efficient shop-floor data collection on any device including touch screens, bar-code scanners, RFID, tablets and interfaces to automated equipment

>Remove paper, spreadsheets and manual processes to create a paperless factory

>Base decisions on information that is more comprehensive, more accurate and more up-to-date than ever before

Quality and Compliance Management

FEATURES

>Quality checks

>Electronic device history records (eDHR)

>Non-conformance and issue management

>Detailed manufacturing workflow definition and enforcement

>Document links

>Rework routings

>Rework recording

BENEFITS

>Operators are always presented with the latest version of instructions and documentation

>Ensure that the optimum sequence of operations is consistently followed

>‘Active’ skills matrix to ensure that operators only work on tasks they are qualified to perform

>Enforced quality checks and workflow for non-conformances

>Auditable evidence that correct procedures have been followed

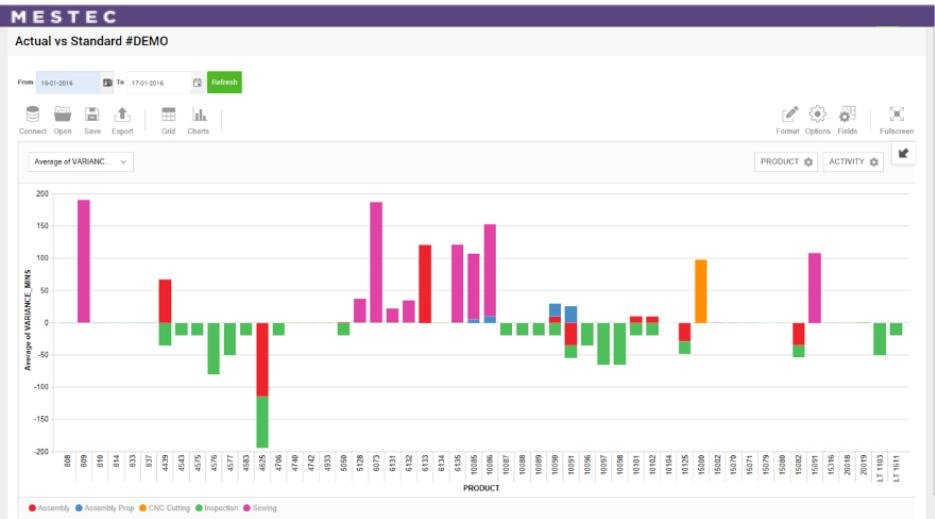

Manufacturing KPIs and Performance Management

FEATURES

Mestec has > 130 standard dashboards and KPIs including:

>Labour utilisation, performance and productivity

>On-time delivery performance

>Right-first-time

>Current schedule adherence

>WIP status & tracking

>Asset performance including OEE

>Actual vs standard cost analysis

>Scrap & rejects

>Rework and scrap cost

>Downtime analysis

>Bottleneck identification

>Production output

BENEFITS

>Real-time dashboards and alerts trigger action before problems escalate

>Information at finger tips: no need for progress-chasing

>No spreadsheets required; just a browser

>No compiling reports in Excel

>Drive continuous improvement

>Give staff the information they need to make better decisions

>Highlight opportunities for productivity improvement in real-time

>Create a continuous improvement culture with live shop-floor big-screen dashboards

>See rapid improvements in quality, cost and delivery