The Industry’s best WMS for Food & Beverage Manufacturers

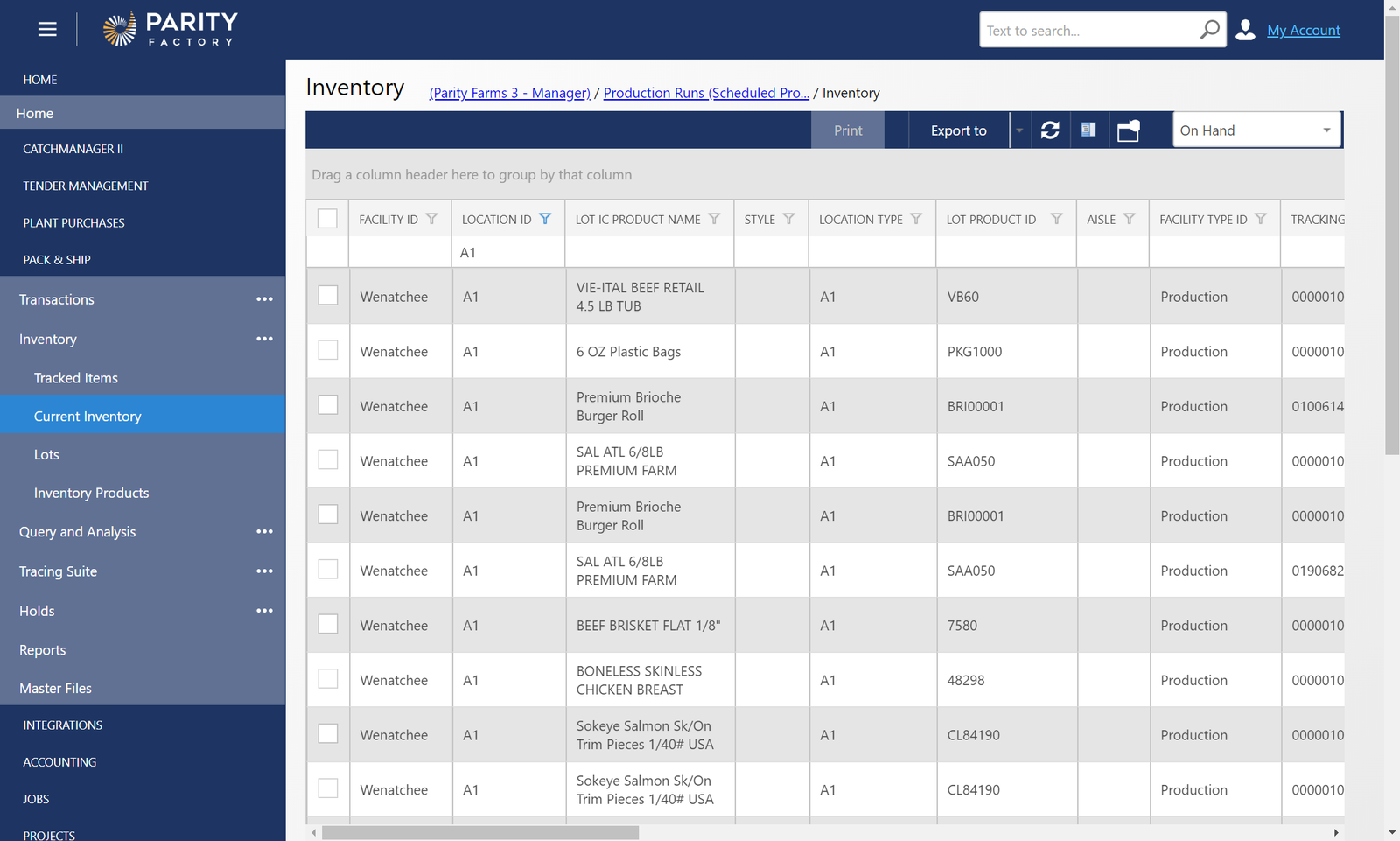

ParityFactory simplifies materials control in food production plants—increasing the efficiency of shop floor workers, reducing errors, and giving managers the accurate inventory reports and lot tracing they need. ParityFactory’s NetSuite integration automates the tracking and management of materials as they flow from receiving through shipping.

Key Benefits

Dramatically Reduce Inventory Variance: The majority of ParityFactory’s clients go from weekly physical counts to twice a year. That’s how dramatic a difference they experience in inventory accuracy. Not only does it make receiving and shipping more accurate, it also makes it faster.

Prevent Production and Shipment Errors: ParityFactory’s integrated barcoding and scanning software prevent users from scanning the wrong ingredients into a production run. It also prevents the team from adding the wrong finished goods to a shipment. All while automatically enforcing FIFO or FEFO.

IoT Integrations Eliminate Manual Data Entry: In addition to getting rid of paper and moving to barcoding, ParityFactory can also integrate truck scale, factory scales, or robotics to automatically capture critical data without human intervention.

Integrated with NetSuite: ParityFactory has worked closely with the NetSuite team to build out the integration to enable accurate inventory, as well as detailed yields and costing, empowering the executive team to make mission critical decisions with high confidence in the data.

Customer Quote

“With rapidly rising operating costs, automation is an imperative in our plant. ParityFactory provides us with a stable operating platform in processing, case-up, and shipping/receiving, which will allow us to explore numerous opportunities for improved efficiencies in our operations.”

—Don Goodfellow, Alyeska Seafoods